THE DUNNAGE BAG OF TOMORROW – TODAY

First GrizzlyBag® with powerful Sealing Tape Technology

► WELDING INSTEAD OF SEWING FOR HIGHEST STRENGTH ◄

|  |  |

Powerful Advantages |

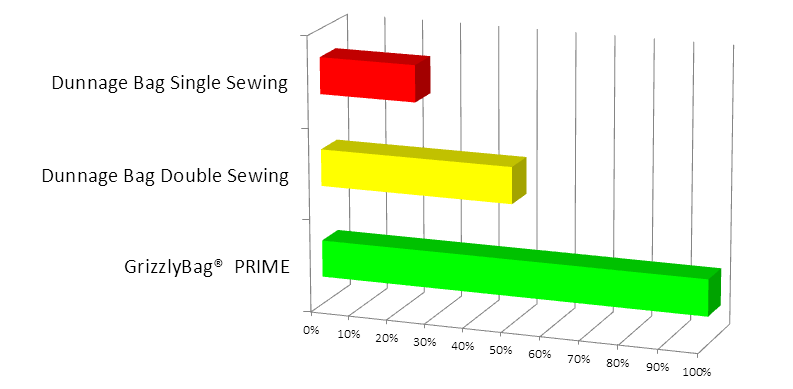

Powerful Strength |

|

Powerful Innovations |

Based on our more than 25 years of experience, we have developed a dunnage bag made of PP that uses a sealing tape instead of stitching. In addition, we have managed to reduce the weight of the PP fabric and the PE inliner, thus reducing the amount of material used by 50%. Based on high-tech polymers of the latest developments and state-of-the-art production lines, our unique chemical formula is used to weave, coat and close the PP outer shell of the dunnage bag. Also the patented (!) lighter PE inliner has a special formulation of reinforced polymers with very high specifications for puncture resistance, tensile strength and elongation. |

Powerful Dimensions

REQUEST YOUR POWERFUL OFFER NOW ►

FAQ – Dunnage Bags

The Bag is placed in the loading gap. The Bag is then filled with air using a filling device. The Bag expands in the gap. The pressure in the Bag stabilizes the load. The load can no longer tilt or slip.

In the following table you can see the maximum free spaces (gaps) which our dunnage bags can fill:

| Width of the dunnage bag | Free space (loading gap) |

| 60 cm | up to 20 cm |

| 90 cm | up to 35 cm |

| 120 cm | up to 45 cm |

| 150 cm | up to 55 cm |